We impart unique properties to Al-, Mg-, Ti-products due to the surface treatment using microarc oxidation method (MAO-MANEL)

Application

Click on a part

to cover it

to cover it

MAO-MANEL production

Increased protective and decorative properties

Protective and decorative properties are higher in comparison with the electroplated and paint coatings

Machining parts up to 17 m²

Machining parts from 0.5 cm²till 17 m²

Increasing scope

Increasing scope of Al-, Ti-, and Mg-parts due to MAO-coating

Complex geometry parts process

Обработка деталей сложной геометрии, глухих и сквозных отверстий, резьб

Al-, Ti-, Mg- process

Ability to process aluminum, titanium, magnesium alloys

Finish coating

Getting the topcoat in one technological operation

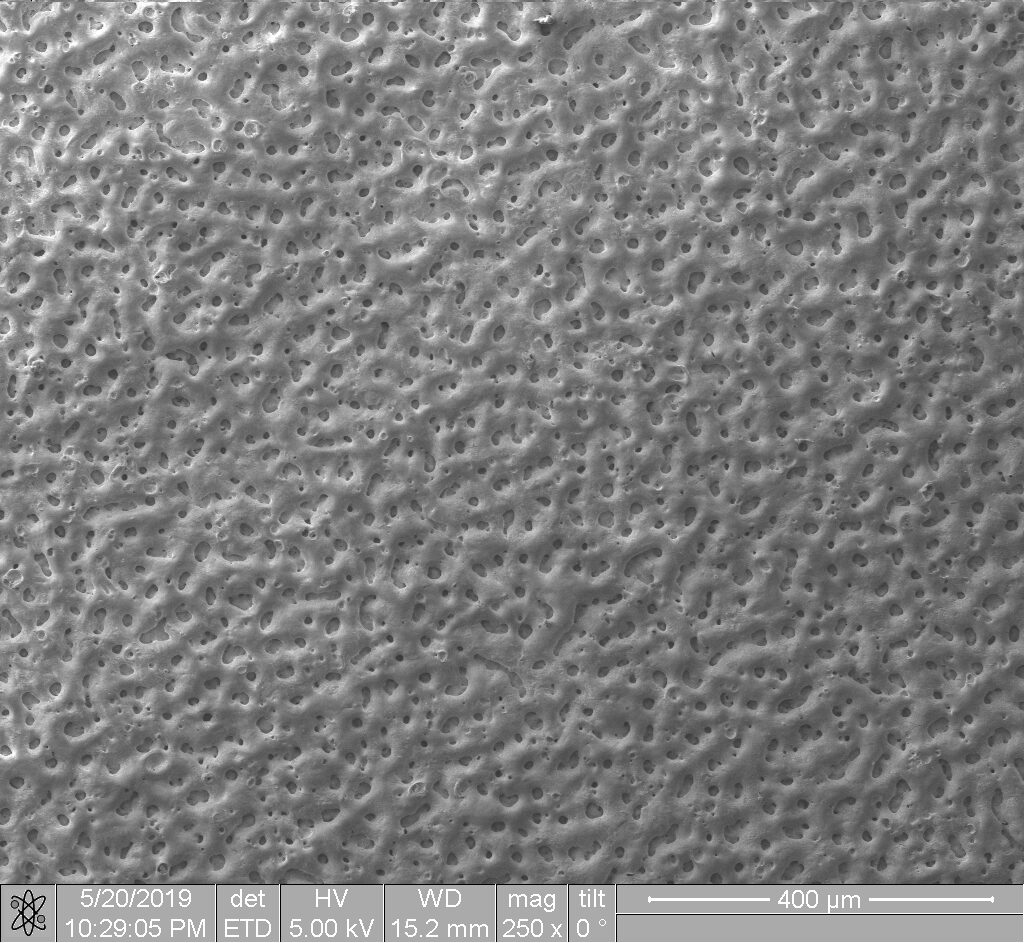

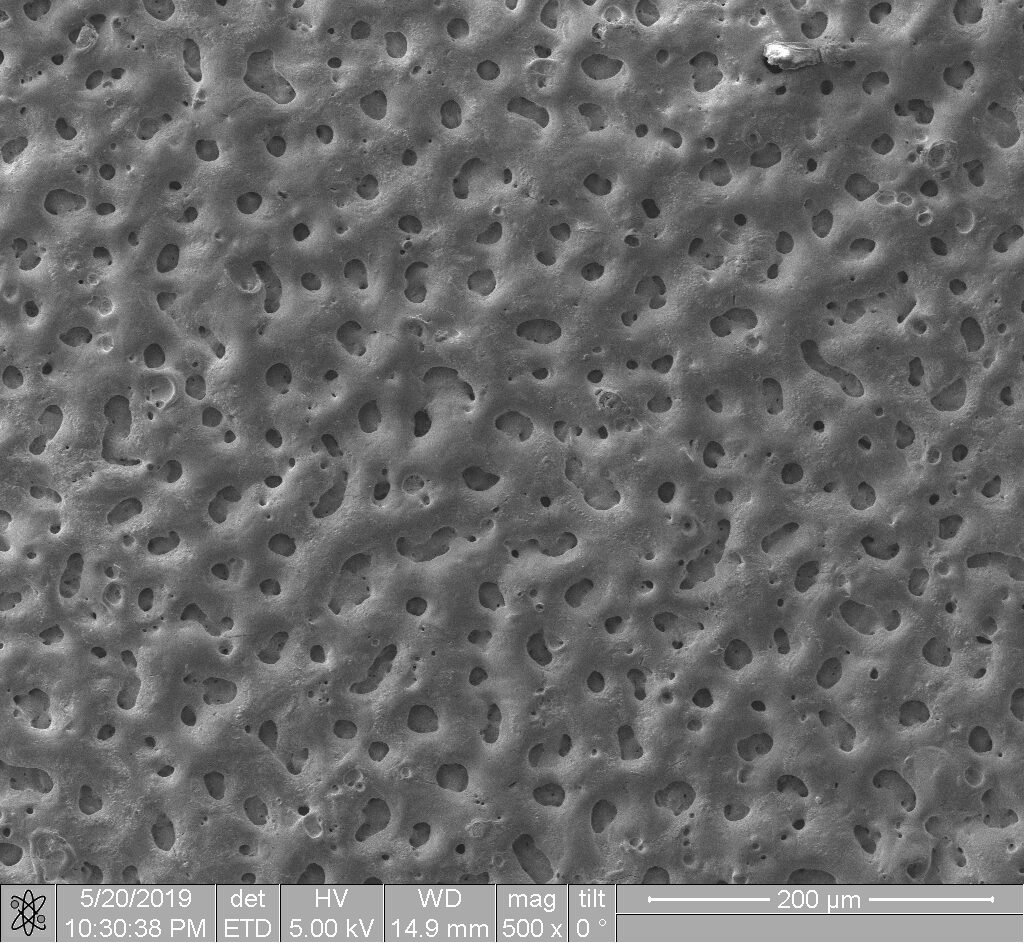

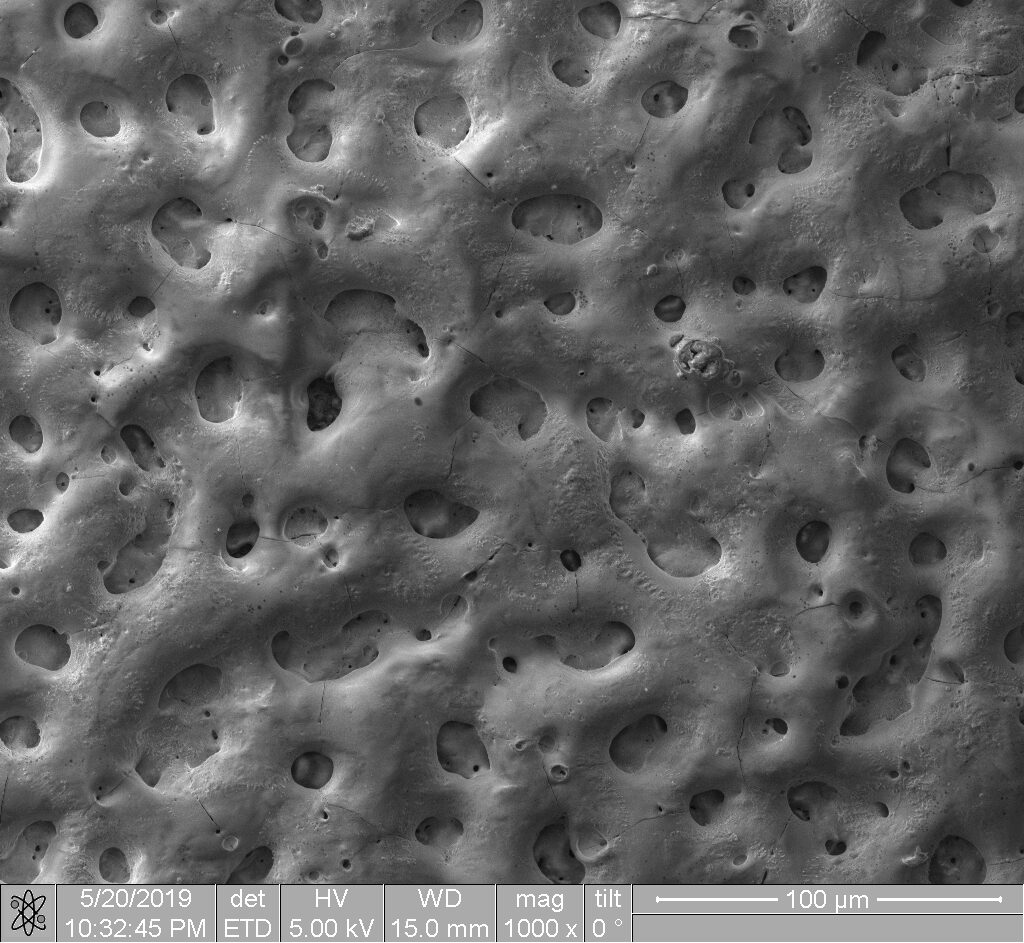

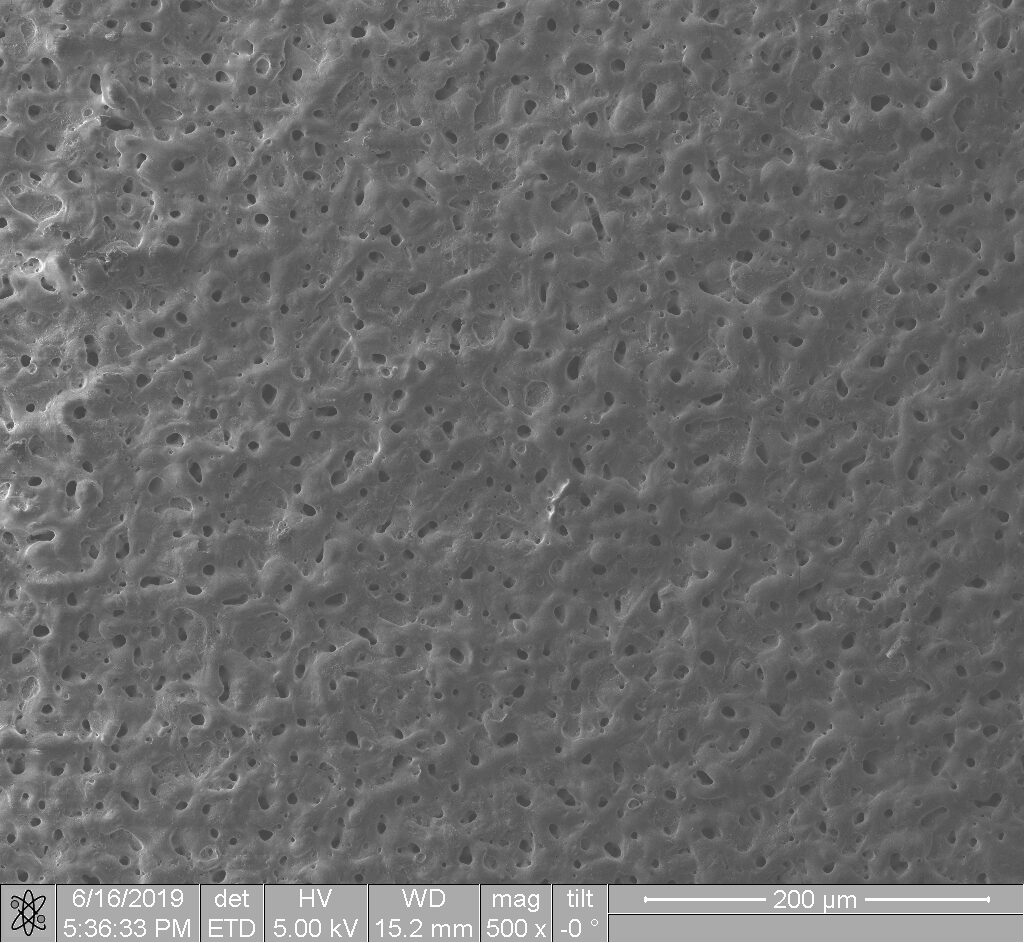

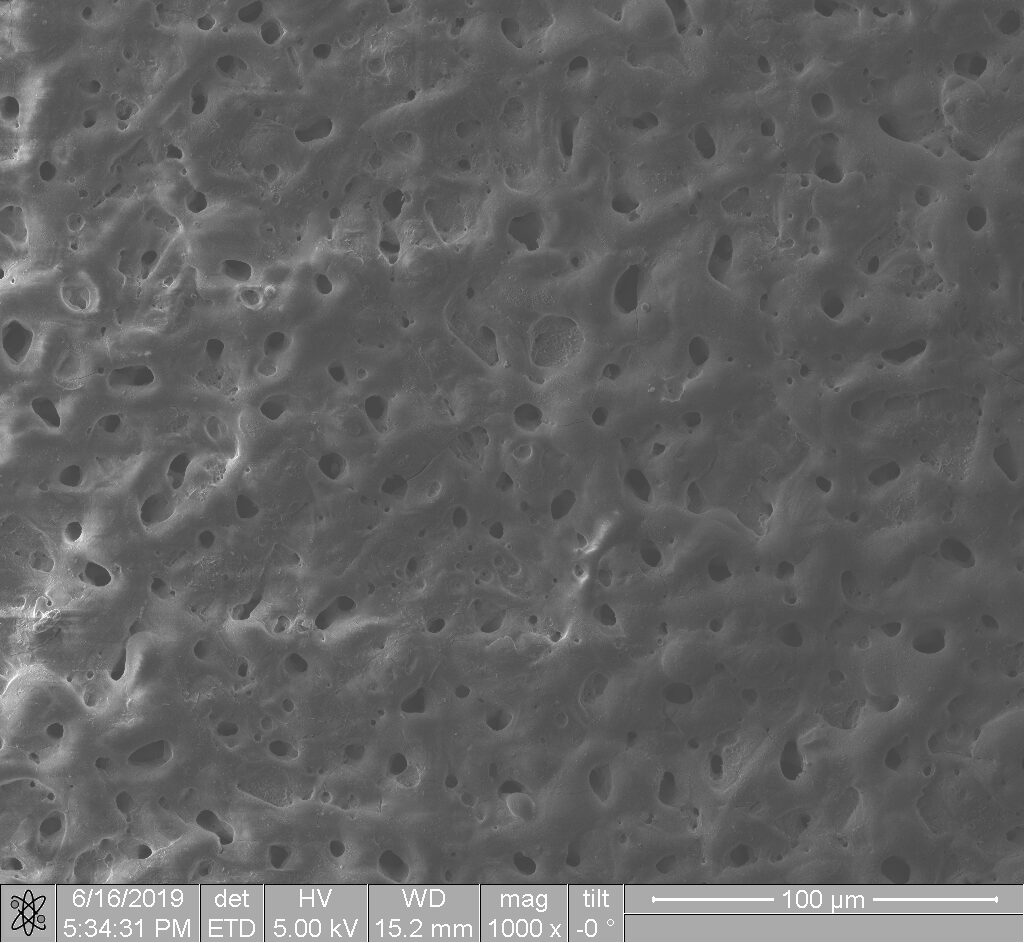

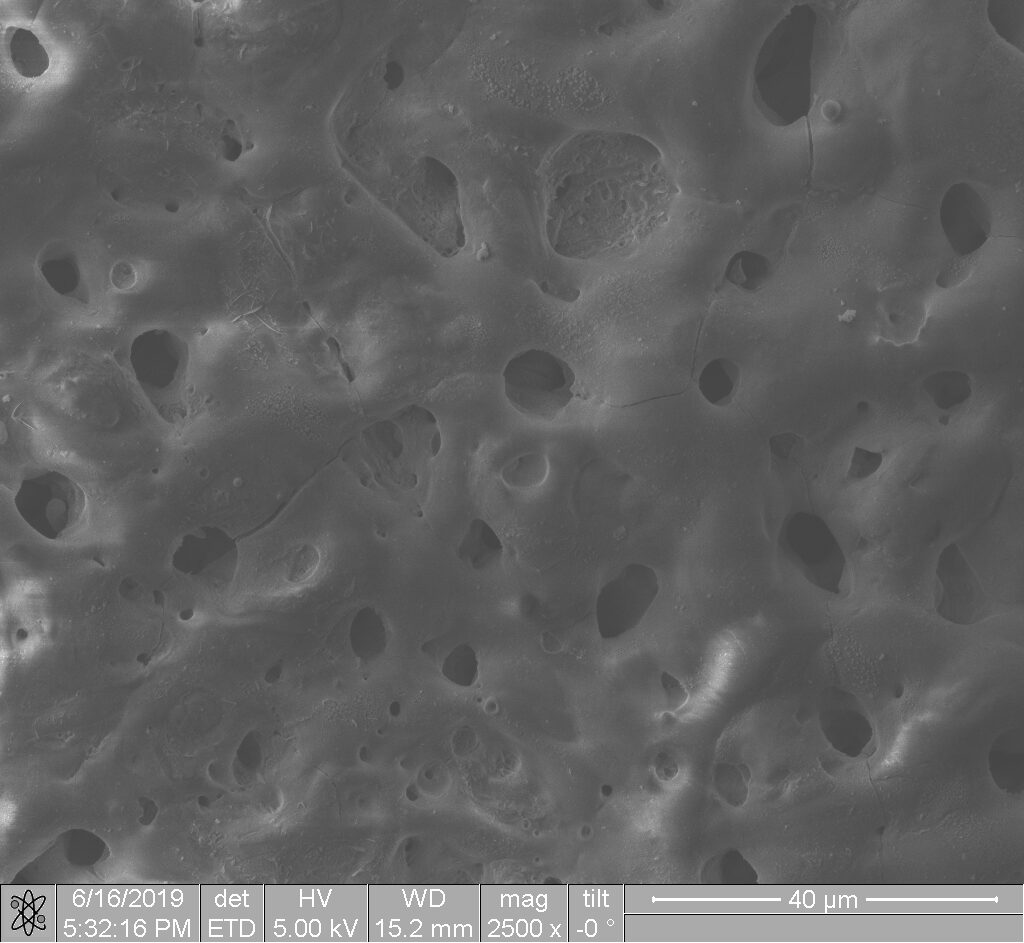

ZOOM:

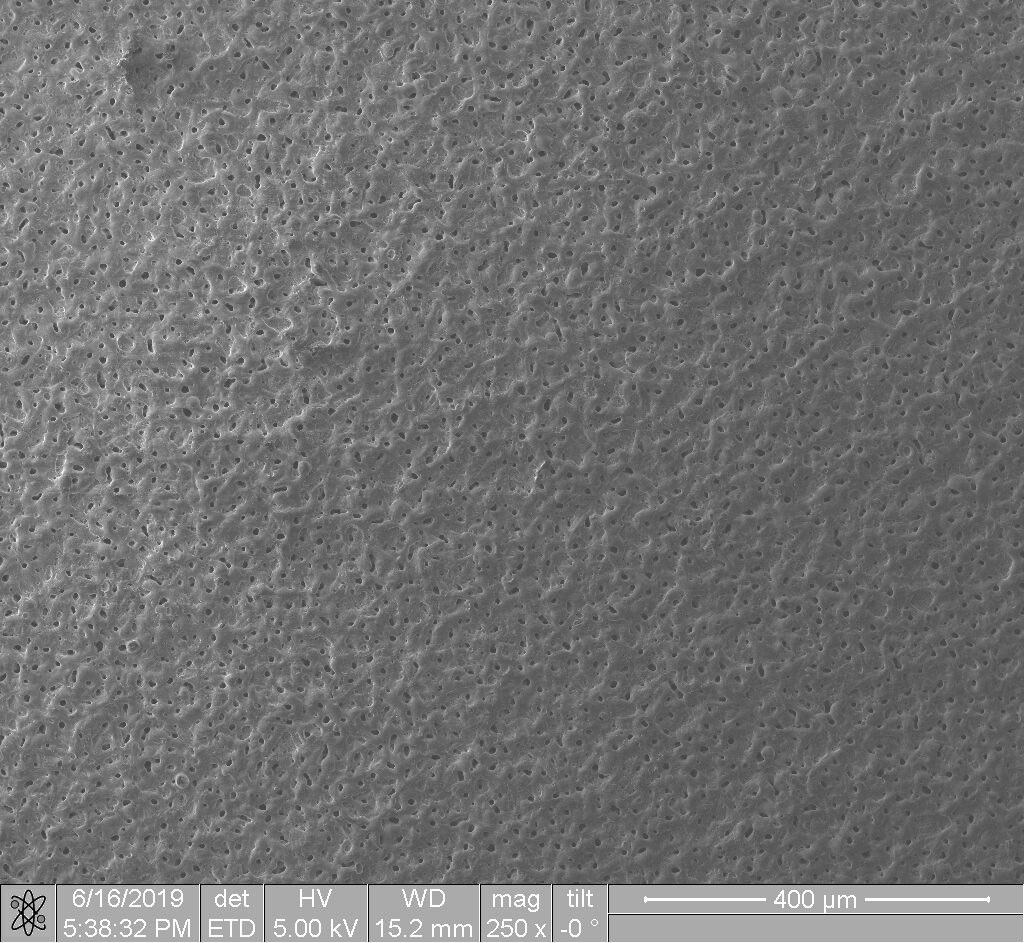

X250

X500

X1000

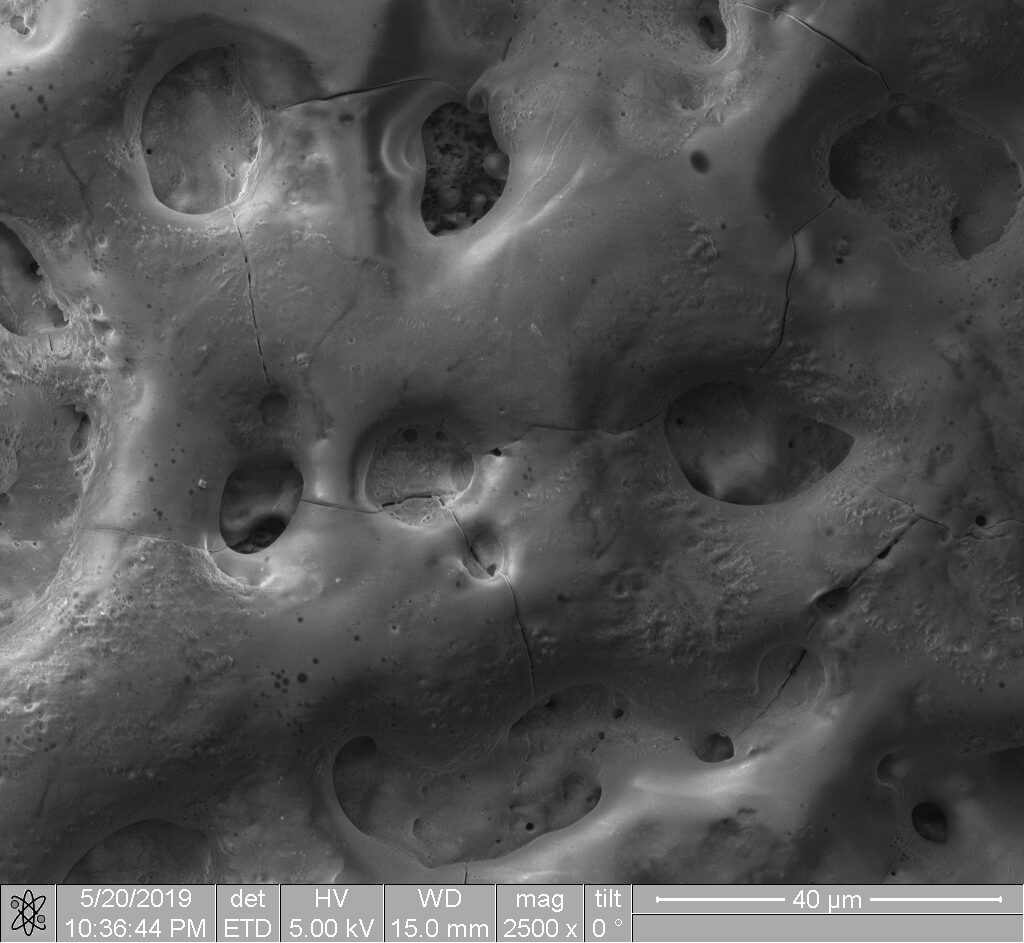

X2500

5-150 mkm

Coating thickness

5-30 %

Coating porosity

0,32-2 Ra

Coating roughness

97 %

Coating blackness

up to 2000 V

Breakdown voltage

720-2000 h

Corrosion resistance

up to 1500 HV

Coating microhardness

250 cycles

Thermal cyclicity at t=280 °C

ZOOM:

X250

X500

X1000

X2500

We coat Al-, Ti- and Mg-parts

Free of cost trial coating

Batch work pieces coating

1-5 days

3 days

What we do?

We supply equipment for MAO-coating

Price quote

Equipment manufacturing, delivery and starting

4-6 mons

3 days

Development of individual

MAO-coatings

MAO-coatings

The MANEL company, continuously developing the technology of micro-arc oxidation of parts made of aluminum, titanium and magnesium, offers its customers cooperation in various directions.

Selection of electrolytes and treatment modes

Testing

Fill out the form below

About us

Our goal is to be a leader in the field of MAO industry implementation, offering customers competitive advantages due to MAO-coatings

10

300

17

3

4

years on the coating market

thousand parts coating via year

m² maximal size of processed surface

thousand m² production areas

own MAO-lines

Наша цель быть лидером в области внедрения МДО в промышленность, предлагая потребителям конкурентные преимущества от использования МДО-покрытий

Наши клиенты

Saint Petersburg

— AO Evrika

— GK SNABZHENIE

— ZASLON

— Radar mms

— OOO NPK

— Energodvizhenie

— OOO PK Brask

— AO Evrika

— GK SNABZHENIE

— ZASLON

— Radar mms

— OOO NPK

— Energodvizhenie

— OOO PK Brask

Customs map

Velikiy Novgorod

— OKB Planeta

Tver

— LUCH

Moscow and region

— OPTON

— AO ZNTC

— AO PKK Milandr

— AO Promtekh-Dubna

— ZAO SuperOks

— MMP IRBIS

— OOO AVM Kontrakt

— OOO Armakon

— OOO Vakuumglou

— OOO Intekhsvyaz'

— OOO LTD Vesttrejd

— OOO NPK TEKHTEST

— OOO NT-MDT

— OOO OJL Enerdzhi

— OOO OSATEK

— OOO Polismart

Kaluga

— ООО ТМ Белоусово Калуга

Tula

— OOO Del'ta-Tek

— PAO Oktava

Voronezh

— AEDON

— OOO KV Sistemy

— OOO NPO Energeticheskaya elektronika

— OOO ENEL

Kirov

— Vertical

Kazan

— KOMZ

Ulyanovsk

— AO UKPB

Ufa

— OOO NPC Astra

Orenburg

— AO PO Strela

Yekaterinburg

— SIAMS

— OOO Kompozitnye materialy

— OOO Tekhnom

— FGUP PO Oktyabr'

Chelyabinsk

— ???

Omsk

— NPC Dinamika

Tomsk

— SIBMASH

— TOMZEL TRANSNEFT'

— NIKOR

— NPP TEK

— AO EleSi

— ZAO Centr tochnoj mekhanoobrabotki

— AO Pribornyj zavod

— NIIPP

— TOMSKKABEL'

— Mikran

— OOO Inkom

— OOO INTEK

— OOO LAB Novator

— OOO LEMZ-T

— OOO Neotekhnika

— OOO NPK Integral

— OOO NPK Introskopiya

— OOO NPK TETA

— OOO NPO Svobodnaya energiya

— OOO OKB Gorizont

— OOO Stal'tom

— OOO TREM Innovacii

— FGBU IO SO RAN

Novosibirsk

— VIL'DE-MEKHANIKS

— Katod

«arnaul

— SiSort

Krasnoyarsk

— OOO NPO Pul'sar

— OOO Tekhnogarant

Irkutsk

— IRZ

Vladivostok

— PAO Dal'pribor

Tolyatti

— LADA FLECT

St. Petersburg

Velikiy Novgorod

Tver

Moscow and region

Kaluga

Tula

Voronezh

Rostov on Don

Kirov

Kazan

Ulyanovsk

Tolyatti

Ufa

Yekaterinburg

Chelyabinsk

Omsk

Tomsk

Novosibirsk

Barnaul

Krasnoyarsk

Irkutsk

Orenburg

Rostov on Don

— VNIIR

Vladivostok

Feedbacks

Online survey

The results help us to improve the microarc oxidation technology according your needs

Which properties of MAO coatings are interesting for You?

News